VR Warehouse Health, Safety & Environmental (HSE) Training

With the help of total immersion into virtual reality, resulting in an overwhelming

impression of being physically present in a non-physical world, employees can be

well prepared for their future duties, like inspection and maintenance of

a warehouse environment. In VR they can learn how to use the infrastructure

in a safe way and how to react in hazardous situations in case of malfunction.

With the help of total immersion into virtual reality, resulting in an overwhelming

impression of being physically present in a non-physical world, employees can be

well prepared for their future duties, like inspection and maintenance of

a warehouse environment. In VR they can learn how to use the infrastructure

in a safe way and how to react in hazardous situations in case of malfunction.

Furthermore, they can practice specific situations that may happen in their workplace, for example, a fire alarm, machine failure or even a terrorist attack. A participant will gain self-confidence during an interactive training in virtual reality. The user has enough time to practice all the specific behaviours and learn how to tackle stress.

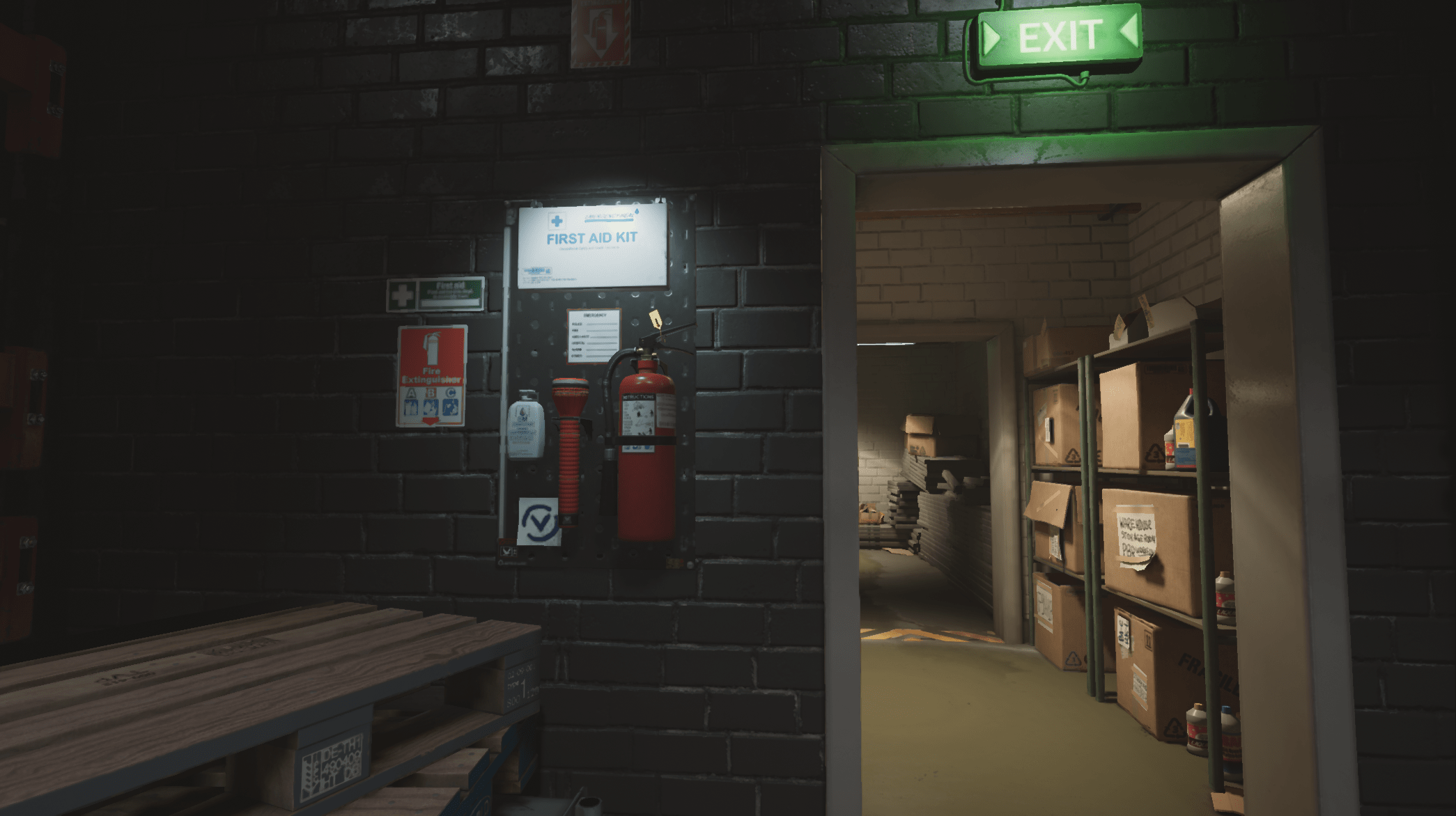

In virtual reality it’s possible to show places and elements of an infrastructure

that are difficult to see (whether for security or environmental reasons).

The user can interact with the environment by using special controllers.

They can grab things, open doors, move objects, interact with switches etc.

In virtual reality it’s possible to show places and elements of an infrastructure

that are difficult to see (whether for security or environmental reasons).

The user can interact with the environment by using special controllers.

They can grab things, open doors, move objects, interact with switches etc.

The key benefits of this solution include:

- The implementation of Heavy Industry Training in VR saves time and money that is spent on employee training sessions.

- The user is completely immersed in virtual reality, which results in higher engagement of the participant.

- Participants learn by doing, and not only by observing.

- This solution allows a user to learn the topography of an industrial object as well as the details of industrial infrastructure, which can be located miles away from the office.

- A training in VR can be held any time and everywhere, regardless of the weather conditions or distance. There is no need to provide physical access to the infrastructure.

-

During crisis simulations in the real world, industrial objects are excluded

from use. In most cases, this situation is unacceptable. Virtual reality gives

you a chance to conduct a training without causing any problematic situations.

- Due to VR technology you can show places and elements of an infrastructure that are difficult to reach on a daily basis.

- With VR you can demonstrate a manufacturing process (for example: production, assembly, extraction of materials) in a very flexible and realistic way.

- This solution can be extended by the additional features: you can monitor an employee’s activity during a training, see progress and create advanced training reports.